Manufacturing industries face unique challenges when it comes to managing their operations, inventory, and supply chain. That’s where erp software for manufacturers comes in. But what exactly is ERP software, and why is it crucial for manufacturing businesses?

Mục lục

- 1. What is ERP software for manufacturers?

- 2. Importance of implementing ERP software in manufacturing industries

- 3. Key Features of ERP Software for Manufacturers

- 4. Benefits of ERP Software for Manufacturers

- 4.1. Improved Efficiency and Productivity

- 4.2. Streamlined Operations and Reduced Costs

- 4.3. Enhanced Inventory Control and Reduction of Stockouts

- 4.4. Real-time Data and Reporting for Informed Decision Making

- 4.5. Better Collaboration and Communication among Departments

- 4.6. Scalability and Flexibility to Adapt to Business Growth

- 5. Factors to Consider When Choosing ERP Software for Manufacturers

- 6. Case Studies: Successful Implementation of ERP Software for Manufacturers

- 7. Conclusion

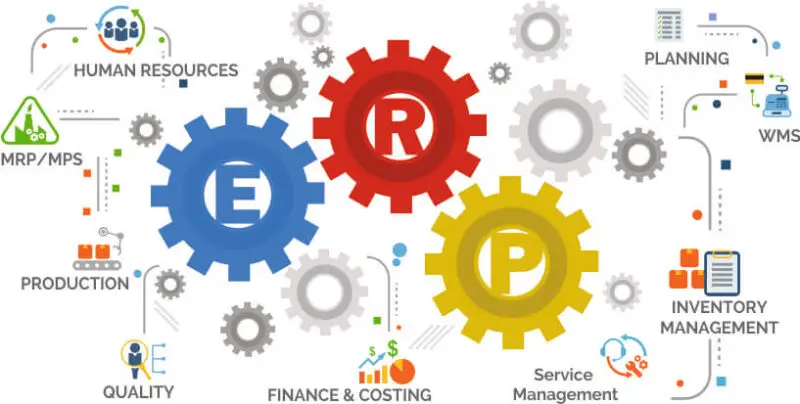

What is ERP software for manufacturers?

ERP, or Enterprise Resource Planning, software is a comprehensive solution designed to integrate and streamline various aspects of a manufacturing business. It provides a centralized platform that allows manufacturers to manage their operations, production planning, inventory, finances, and customer relationships all in one place.

By automating and optimizing processes, ERP software empowers manufacturers to improve efficiency, reduce costs, and enhance productivity. It eliminates the need for manual data entry and allows real-time access to critical information, enabling better decision-making and driving overall business growth.

Importance of implementing ERP software in manufacturing industries

In the competitive manufacturing landscape, staying ahead requires businesses to be agile and responsive. ERP software offers a multitude of benefits that can give manufacturers a competitive edge.

Efficiently managing inventory is crucial for manufacturers to meet customer demands while minimizing costs. ERP software provides robust inventory management capabilities, allowing businesses to track stock levels, monitor usage, and automate reordering processes. With accurate inventory data at your fingertips, you can avoid stockouts and ensure timely deliveries, keeping your customers satisfied.

Moreover, production planning and scheduling can be complex and time-consuming without the right tools. ERP software enables manufacturers to optimize their production processes by creating realistic production plans, scheduling tasks, and allocating resources efficiently. This streamlines operations, minimizes downtime, and maximizes productivity, resulting in faster order fulfillment and improved customer satisfaction.

In conclusion, ERP software is a game-changer for manufacturers, revolutionizing the way they manage their operations, inventory, and supply chain. By implementing ERP software tailored to their specific needs, manufacturers can unlock the full potential of their business, streamline processes, and achieve sustainable growth. Stay tuned to discover the key features and benefits of ERP software for manufacturers in the next section.

Key Features of ERP Software for Manufacturers

To fully grasp the immense benefits of ERP software for manufacturers, it is essential to understand its key features. Let’s dive into the core functionalities that make ERP software a game-changer for the manufacturing industry:

A. Inventory Management

Effective inventory management is vital for manufacturers to meet customer demands while optimizing costs. ERP software provides robust inventory management capabilities, enabling businesses to track stock levels, monitor usage, and automate reordering processes. With real-time visibility into inventory data, manufacturers can avoid stockouts, minimize excess inventory, and ensure timely order fulfillment.

B. Production Planning and Scheduling

Efficient production planning and scheduling are crucial for manufacturers to optimize their operations. ERP software empowers businesses to create realistic production plans, set accurate schedules, and allocate resources effectively. By automating these processes, manufacturers can minimize downtime, maximize productivity, and ensure smooth production flow.

C. Supply Chain Management

A well-managed supply chain is the backbone of any manufacturing business. ERP software offers comprehensive supply chain management capabilities, allowing manufacturers to monitor and control every aspect of their supply chain. From sourcing raw materials to tracking shipments and managing suppliers, ERP software ensures better visibility, reduces lead times, and improves overall supply chain performance.

D. Quality Control and Assurance

Maintaining quality standards is paramount for manufacturers to deliver products that meet customer expectations. ERP software includes robust quality control and assurance modules that enable businesses to monitor and manage quality at every stage of the manufacturing process. From inspections and testing to compliance tracking and corrective actions, ERP software ensures consistent product quality and regulatory compliance.

E. Financial Management and Reporting

Managing finances effectively is crucial for the long-term success of manufacturing businesses. ERP software provides comprehensive financial management capabilities, allowing manufacturers to track expenses, manage budgets, and generate accurate financial reports. With real-time financial data at hand, businesses can make informed decisions, identify cost-saving opportunities, and ensure financial stability.

F. Customer Relationship Management (CRM)

Building strong customer relationships is vital for manufacturers to thrive in a competitive market. ERP software offers integrated CRM functionality, enabling businesses to manage customer interactions, track sales, and provide exceptional customer service. With a centralized customer database and automated communication tools, manufacturers can enhance customer satisfaction and drive repeat business.

G. Integration with Other Systems

ERP software seamlessly integrates with other essential systems, such as HR, payroll, and e-commerce platforms. This integration eliminates data silos, improves data accuracy, and enables efficient cross-functional collaboration. By connecting various systems, ERP software creates a unified ecosystem that streamlines operations, enhances productivity, and boosts overall business performance.

Stay tuned to explore the incredible benefits of ERP software for manufacturers in the next section.

Benefits of ERP Software for Manufacturers

As manufacturers face increasing competition and evolving customer demands, implementing ERP software can bring a multitude of benefits to their operations. Let’s explore some of the key advantages that ERP software offers:

Improved Efficiency and Productivity

ERP software automates various manual tasks and processes, eliminating the need for time-consuming paperwork and reducing human errors. By streamlining operations and providing real-time visibility into the entire manufacturing process, ERP software enables employees to work more efficiently. With automated workflows, streamlined communication, and optimized resource allocation, manufacturers can achieve higher productivity levels and faster turnaround times.

Streamlined Operations and Reduced Costs

Manufacturers often deal with complex supply chains, multiple departments, and numerous processes. ERP software simplifies and integrates these operations, ensuring seamless coordination between different departments and processes. This streamlined approach helps eliminate bottlenecks, minimize downtime, and reduce costs associated with inefficiencies or errors. By optimizing workflows and automating routine tasks, manufacturers can allocate resources more effectively and achieve cost savings.

Enhanced Inventory Control and Reduction of Stockouts

Managing inventory is a critical aspect of manufacturing. ERP software provides manufacturers with real-time visibility into their inventory levels, allowing them to track stock, monitor usage, and automate replenishment processes. With accurate inventory data at their fingertips, manufacturers can avoid stockouts and ensure timely deliveries to customers. This enhanced control over inventory leads to improved customer satisfaction, reduced carrying costs, and minimized wastage.

Real-time Data and Reporting for Informed Decision Making

ERP software consolidates data from various departments and processes, providing manufacturers with real-time insights into their business performance. With access to accurate and up-to-date information, decision-makers can make informed choices and respond quickly to market changes. ERP software also offers robust reporting capabilities, enabling manufacturers to generate customized reports, analyze trends, and identify areas for improvement. This data-driven approach facilitates proactive decision-making and helps manufacturers stay ahead of the competition.

Better Collaboration and Communication among Departments

In a manufacturing environment, effective collaboration and communication between different departments are vital for success. ERP software breaks down data silos and fosters cross-functional collaboration by providing a centralized platform for sharing information. By enabling seamless communication and data exchange between departments such as production, inventory, finance, and sales, ERP software promotes better teamwork, reduces miscommunication, and enhances overall efficiency.

Scalability and Flexibility to Adapt to Business Growth

Manufacturing businesses constantly evolve and grow. ERP software offers scalability and flexibility to accommodate changing business needs. Whether you expand into new markets, introduce new product lines, or acquire new subsidiaries, ERP software can adapt and scale alongside your business. This scalability ensures that your software investment remains valuable and supports your growth journey.

In the next section, we will delve into the factors that manufacturers should consider when choosing ERP software tailored to their specific needs. Stay tuned!

Factors to Consider When Choosing ERP Software for Manufacturers

When selecting the right ERP software for your manufacturing business, it’s crucial to consider several factors that align with your specific needs. Here are some key considerations to keep in mind:

A. Industry-Specific Functionality

Every manufacturing industry has its unique requirements and processes. Look for ERP software that offers industry-specific functionality tailored to your niche. Whether you’re in automotive, electronics, or food production, having software that understands and addresses your specific challenges will ensure a smoother implementation and better results.

B. Customization Options

No two manufacturing businesses are the same, so it’s essential to have ERP software that can be customized to fit your unique workflows and processes. Look for software that offers flexibility in terms of configuration, allowing you to adapt the system to match your business requirements. This will ensure a seamless integration with your existing operations and maximize efficiency.

C. User-Friendly Interface and Ease of Implementation

Implementing new software can be a daunting task, but choosing an ERP solution with a user-friendly interface can make the transition smoother. Look for software that offers an intuitive and easy-to-navigate interface, reducing the learning curve for your employees. Additionally, consider the implementation process itself. Opt for software that provides comprehensive implementation support and training to ensure a successful adoption.

D. Integration Capabilities with Existing Systems

A crucial aspect of selecting ERP software for manufacturers is its ability to integrate with your existing systems. Consider the software’s compatibility with your current infrastructure, such as accounting software, CRM systems, or production machinery. Seamless integration will prevent data silos and enable real-time information sharing across departments, enhancing overall operational efficiency.

E. Vendor Support and Training

Choosing an ERP software vendor that offers reliable support and training is vital for a successful implementation. Look for vendors with a proven track record of providing ongoing support, regular updates, and responsive customer service. This will ensure that you have the necessary assistance whenever you encounter issues or require additional training.

F. Cost and Return on Investment

Lastly, consider the cost of implementing ERP software and the potential return on investment (ROI) it can bring to your business. Evaluate the pricing structure, including licensing fees, maintenance costs, and any additional modules or add-ons. Assess the potential ROI by considering the efficiency gains, cost savings, and improved productivity that the software can deliver.

By carefully considering these factors, you can choose an ERP software solution that aligns with your manufacturing business’s needs and sets you up for long-term success. Stay tuned to explore real-life case studies showcasing the successful implementation of ERP software for manufacturers in the next section.

Case Studies: Successful Implementation of ERP Software for Manufacturers

When it comes to implementing ERP software for manufacturers, real-life success stories can provide valuable insights into the benefits and impact it can have on businesses. Let’s explore a few case studies that highlight the positive outcomes achieved through ERP software adoption.

Company A: Increased Efficiency and Reduced Lead Times

Company A, a leading manufacturer in the automotive industry, faced challenges in streamlining their production processes and reducing lead times. By implementing ERP software, they were able to achieve significant improvements. The software enabled them to automate their production planning and scheduling, resulting in better resource allocation and reduced downtime. With real-time visibility into their operations, they could quickly identify bottlenecks and make informed decisions to optimize efficiency. As a result, Company A experienced a substantial reduction in lead times, allowing them to meet customer demands more efficiently and gain a competitive advantage in the market.

Company B: Improved Quality Control and Compliance

For Company B, a pharmaceutical manufacturer, ensuring product quality and compliance with strict regulations was paramount. Prior to implementing ERP software, they struggled with manual record-keeping and lacked real-time visibility into their quality control processes. ERP software transformed their operations by providing a centralized system to manage quality control and assurance. It automated data collection, facilitated real-time monitoring, and enabled comprehensive traceability of materials throughout the production cycle. As a result, Company B achieved improved quality control, reduced errors, and enhanced compliance with regulatory standards, fostering customer trust and loyalty.

Company C: Enhanced Supply Chain Visibility and Optimization

Company C, a global electronics manufacturer, faced challenges in managing their complex supply chain. They lacked visibility into their suppliers, inventory levels, and order fulfillment processes. ERP software enabled them to gain complete visibility into their supply chain, from procurement to delivery. With accurate and real-time data, they could identify potential bottlenecks, optimize inventory levels, and make data-driven decisions to improve their supply chain performance. As a result, Company C experienced enhanced supply chain visibility, reduced costs, and improved customer satisfaction through timely deliveries.

In conclusion, these case studies demonstrate the tangible benefits of ERP software for manufacturers. From increased efficiency and reduced lead times to improved quality control and enhanced supply chain optimization, ERP software has the potential to transform manufacturing businesses, improve their competitiveness, and drive sustainable growth. Stay tuned to discover the key factors to consider when choosing the right ERP software for your manufacturing needs.

Conclusion

In today’s fast-paced manufacturing landscape, implementing the right ERP software is essential for staying competitive and thriving in the industry. ERP software for manufacturers offers a range of benefits that streamline operations, enhance productivity, and drive business growth.

By harnessing the power of ERP software, manufacturers can efficiently manage their inventory, production planning, supply chain, and financial processes. The centralized platform provided by ERP software enables real-time data and reporting, empowering businesses to make informed decisions and optimize their operations.

The benefits of ERP software for manufacturers are numerous. It improves efficiency and productivity by automating manual tasks and streamlining processes. With better inventory control, manufacturers can reduce stockouts and ensure timely deliveries to customers, enhancing satisfaction and loyalty.

Real-time data and reporting provided by ERP software enable manufacturers to have full visibility into their operations, helping them make data-driven decisions. Improved collaboration and communication among departments further enhance operational efficiency and reduce errors.

Scalability and flexibility are crucial for manufacturers as they grow and adapt to changing market conditions. ERP software offers the ability to scale effortlessly, accommodating business growth without disruption.

When choosing an ERP software solution for your manufacturing business, consider industry-specific functionality, customization options, user-friendliness, integration capabilities, vendor support, and cost-effectiveness. These factors will ensure that the ERP software aligns with your unique manufacturing needs and drives the desired outcomes.

At erp.ebest.vn, we understand the challenges faced by manufacturers and offer a comprehensive ERP software solution designed specifically for the industry. With our expertise and commitment to delivering high-quality software, we can help streamline your operations, boost productivity, and propel your manufacturing business to new heights.